Siddament V2

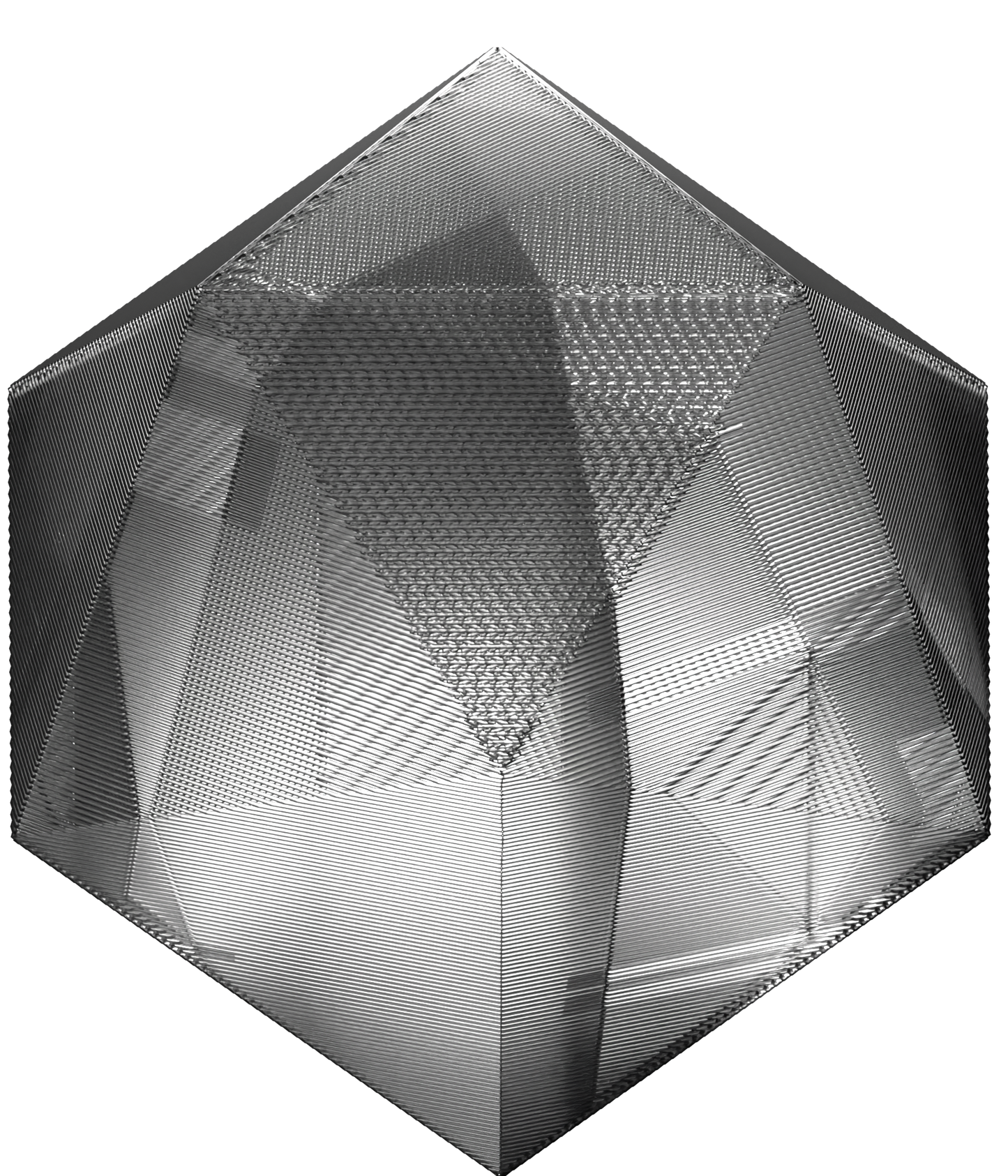

PCTG Transparent

PCTG Transparent

187 in stock

Couldn't load pickup availability

Transparent PCTG Filament – High clarity with unbeatable strength! This filament offers exceptional impact resistance and transparency, making it perfect for projects that need both durability and an aesthetically clear finish. PCTG’s clarity stands out from typical PETG filaments, and its toughness ensures that your prints can handle stress without cracking or breaking.

Sidd's Notes and Applications:

This transparent filament offers a pristine, glass-like finish that can be used in household items, display models, and functional parts where both strength and aesthetics are critical. Whether you're printing light-diffusing lampshades, display cases, or durable containers, PCTG delivers superior toughness. Keep the printed part in temperatures below 76°C for optimal performance.

Below is a ChatGPT generated description of PCTG to give you ideas on its strengths

PCTG (Polycyclohexylenedimethylene Terephthalate Glycol-modified) is a glycol-modified variant of PCT, which is similar to PETG (Polyethylene Terephthalate Glycol-modified), but with enhanced mechanical properties. It is becoming popular in 3D printing due to its improved impact resistance, clarity, and ease of use compared to other filaments. Here’s a breakdown of its properties:

Properties of PCTG 3D Printer Filament:

-

Impact Resistance:

- PCTG has higher impact resistance compared to PETG, making it more durable and less likely to crack or shatter under stress.

- It can withstand impact better, making it suitable for applications requiring toughness.

-

Printability:

- It is similar to PETG in terms of ease of printing, with minimal warping and excellent layer adhesion.

- Typically prints at temperatures between 230°C and 250°C, with a heated bed temperature between 70°C and 85°C.

-

Clarity and Transparency:

- PCTG has high optical clarity, offering a clearer, shinier finish compared to PETG, which can be beneficial for aesthetic or translucent prints.

-

Flexibility:

- While it is not as flexible as TPU (Thermoplastic Polyurethane), PCTG offers a good balance between rigidity and flexibility, making it more durable and resilient than PETG.

-

Chemical Resistance:

- It has good chemical resistance, similar to PETG, which makes it suitable for parts exposed to a variety of chemicals and solvents.

-

Heat Resistance:

- PCTG has slightly lower heat resistance than PETG, with a glass transition temperature around 76°C–80°C. It may deform under higher temperatures compared to other materials like ABS or Nylon.

-

Food Safety:

- Similar to PETG, many PCTG filaments are marketed as food-safe, but you should always check with the manufacturer for specific certifications.

-

Tensile Strength and Durability:

- PCTG offers strong tensile strength and durability, making it suitable for functional parts that need to endure stress and strain.

Applications of PCTG:

- Prototyping and functional parts where impact resistance is important.

- Transparent or translucent parts due to its excellent clarity.

- Consumer products or household items that may experience wear and tear.

- Food containers or utensils, when food-safe variants are used.

Overall, PCTG offers a good balance between ease of printing, durability, and aesthetic finish, making it an excellent alternative to PETG in various applications.

⚠ Colour Variation Disclaimer

| 🔥 Hotend Temperature | 230-255°C |

|---|---|

| ♨️ Heated Bed Temperature | 80-110°C |

| 🏠 Enclosure | Not Required |

| 🛠️ Hardened Nozzle | Not Required |

| 💨 Drying Settings | 50-60°C for 10-12 hours |

| 🎨 Colour Stability | ✅ Stable |

| ⚙️ Diameter | 1.75mm |

| ⚖️ Weight | 1kg |

| 📦 Next Stock Comes | Not Ordered Yet |

V2

V2

Refined filament for precision and consistency.

Engineered consistency

Dimensional stability and colour uniformity between batches.

Ready to print

Open, load, print — stable feed and clean layers.